고객 지원 문서

안전보건자료, 사용자 매뉴얼, 소모품 주문 등 더 많은 정보 확인하기

>150˚C의 열변형 온도를 제공하는 UL94 V0 등급 난연성 블랙 컬러 플라스틱

Figure 4® High Temp 150°C FR Black is a rigid, flame-retardant black material that can be used for production parts requiring UL94 V0 rating as well as FAR 25.853 and 23.853 capability. It provides long-term environmental stability with an injection molded-like surface quality.

This material is recommended for consumer, transportation, and aerospace applications that require performance at high temperatures like brackets, covers, and circuit board housings and covers.

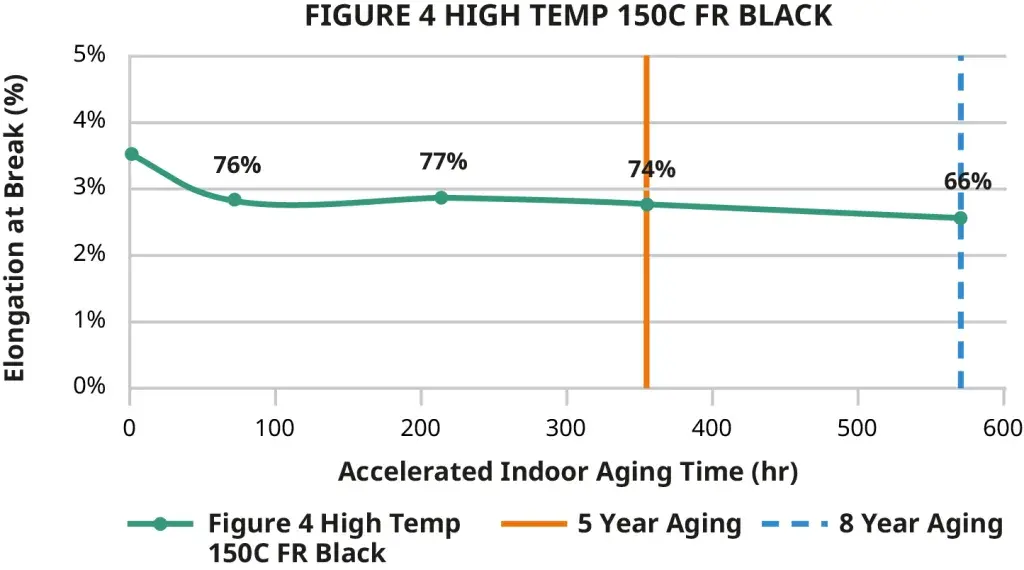

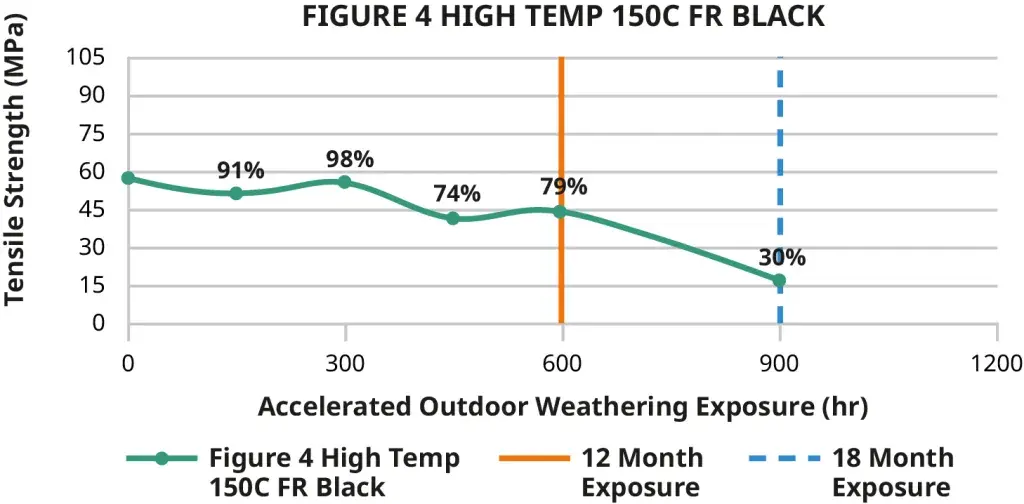

Figure 4 High Temp 150°C FR Black is tested to 8 years of indoor and 1.5 years outdoor mechanical performance per ASTM D4329 and ASTM G194 methods, ensuring that printed parts remain functional and stable for long periods in real-world conditions.

The full suite of mechanical properties is given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties and thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, improving the degree of freedom for part orientation for mechanical properties.

Figure 4 High Temp 150°C FR Black is engineered to give long-term environmental UV and humidity stability and long-lasting black color. This material has been tested for its ability to retain a high percentage of its initial mechanical properties over a period of time. This test data provides real performance conditions to consider for the application or part.

The charts show a sampling of the dataset. The full datasheet includes indoor and outdoor stability data for tensile strength, elongation at break, tensile modulus, and impact strength. The actual data value is on the Y-axis, and data points are a % of the initial value.

Tested per ASTM D4329 standard method.

Tested per ASTM G194 standard method.

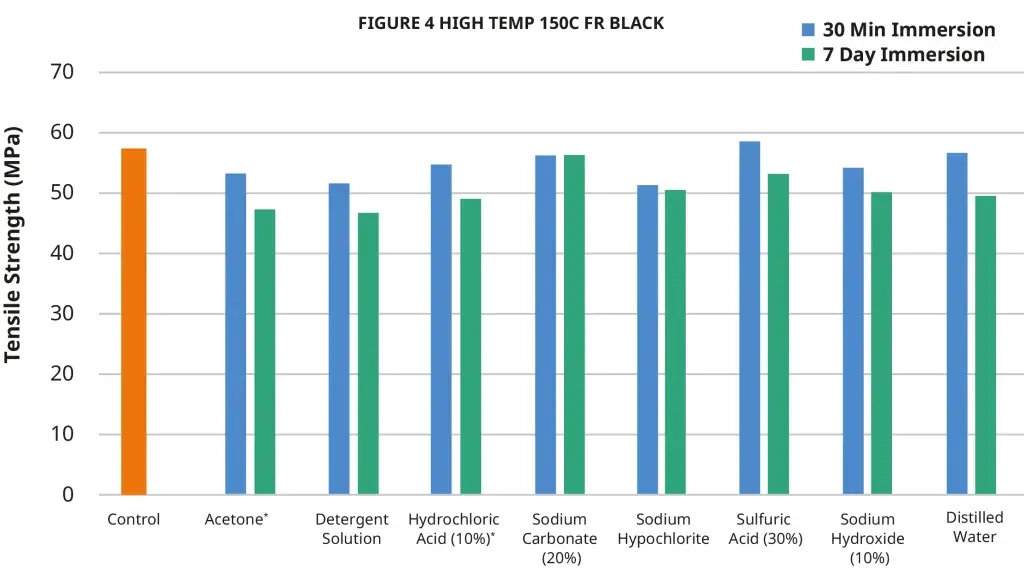

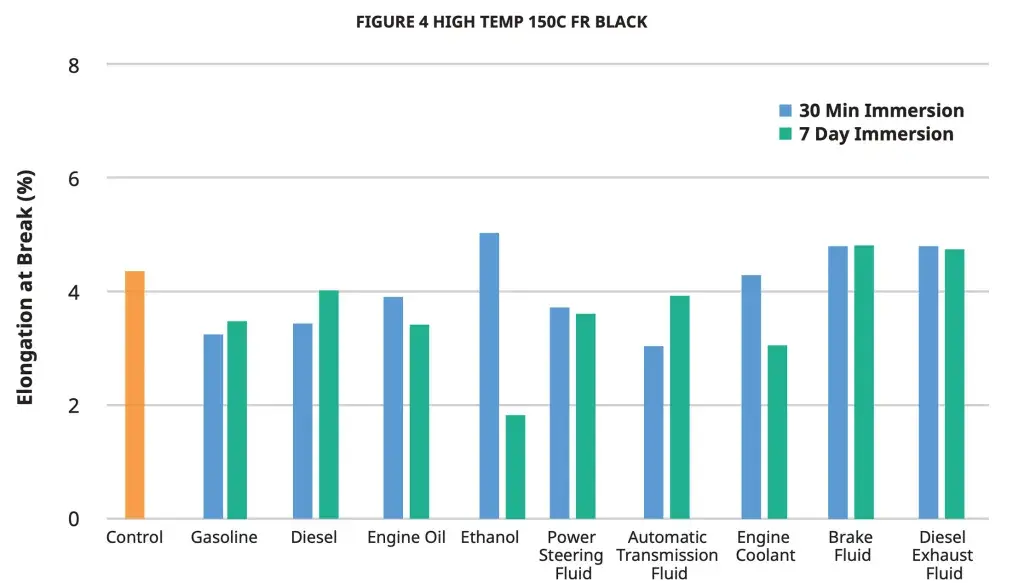

Hydrocarbons and cleaning chemical compatibility can be critical to application compatibility. Figure 4 High Temp 150°C FR Black parts were tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. The full data sheet includes additional data tables for tensile strength, tensile modulus, and elongation at break.

* Note: Not all products and materials are available in all countries – please consult your local sales representative for availability.

생산 부품에 대한 생산 등급, 강성 소재

열 변형 온도가 300°C를 넘어 고내열성을 자랑하는 반투명 플라스틱

높은 안정성, 내구성과 유연성이 뛰어난 플라스틱

사용자 정의가 가능한 업계 최초의 직접 디지털 생산용 완전 통합형 공장 솔루션

비즈니스 성장에 따라 확장 가능하도록 설계된 반자동 3D 제조 솔루션

매우 신속하게 저렴한 비용으로 당일 원형 제작 및 소량 생산

도구가 필요없는 제조를 위한 반복 가능한 정확도로 고속, 고정밀 구현

안전보건자료, 사용자 매뉴얼, 소모품 주문 등 더 많은 정보 확인하기