다양한 MultiJet 소재 선택

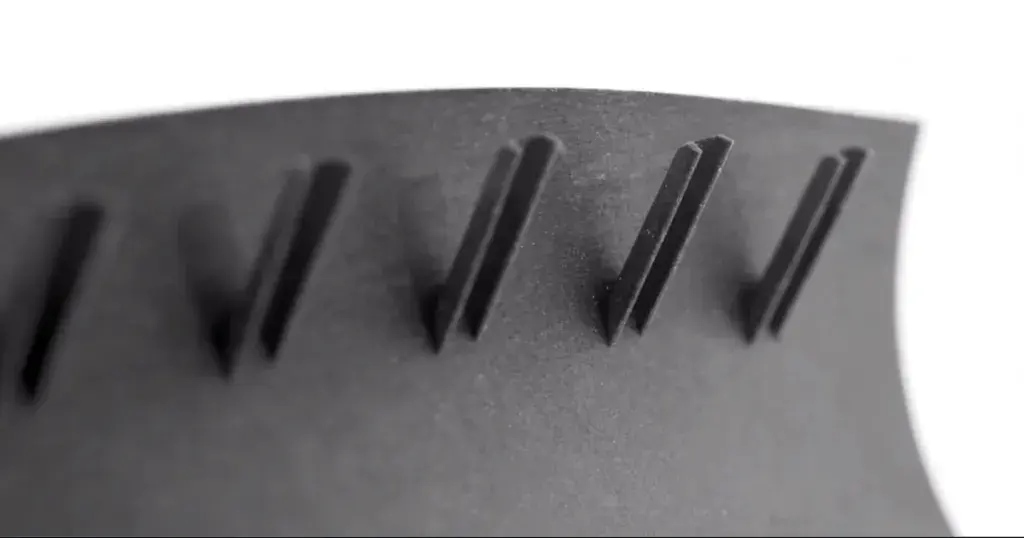

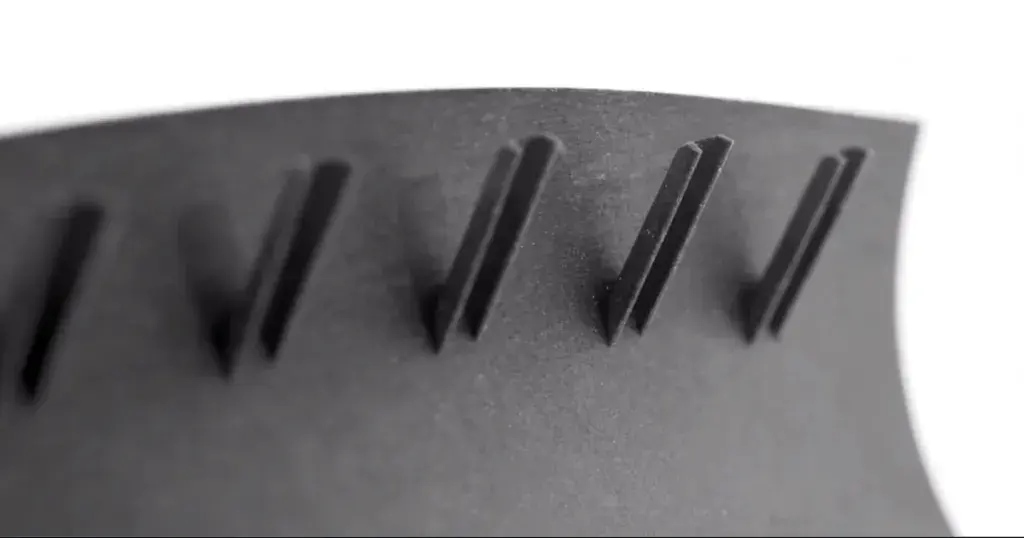

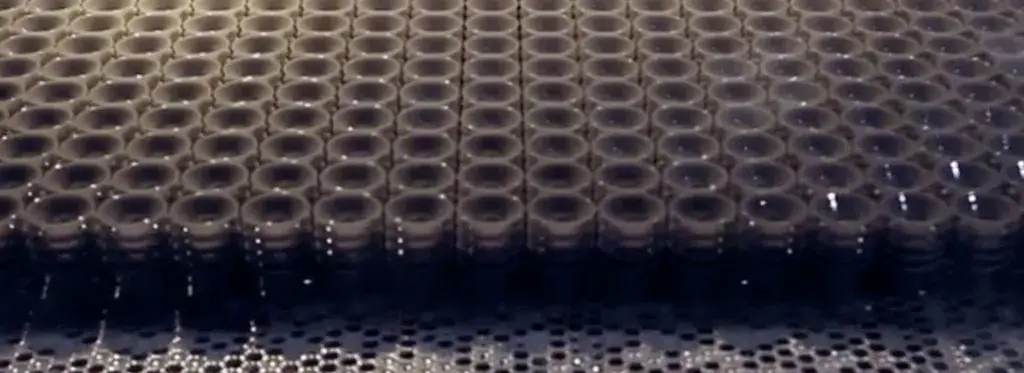

ProJet® MJP 5600 멀티젯 3D 프린터 솔루션은 VisiJet® 재료군 내에서 연성 및 강성 감광성 수지를 동시에 혼합 및 프린트합니다. 이는 뛰어난 기계적 특성을 달성하도록 단일 빌드 및 한 부품의 복셀 수준에서 레이어별로 수행됩니다. 아울러 VisiJet 경질 플라스틱, 탄성 및 복합 재료는 하나의 부품에 다양한 유연도, 재료 투명도 및 차별화된 음영 성능을 제공하도록 설계되었습니다.

ProJet® MJP 5600 멀티젯 3D 프린터 솔루션은 VisiJet® 재료군 내에서 연성 및 강성 감광성 수지를 동시에 혼합 및 프린트합니다. 이는 뛰어난 기계적 특성을 달성하도록 단일 빌드 및 한 부품의 복셀 수준에서 레이어별로 수행됩니다. 아울러 VisiJet 경질 플라스틱, 탄성 및 복합 재료는 하나의 부품에 다양한 유연도, 재료 투명도 및 차별화된 음영 성능을 제공하도록 설계되었습니다.

3D Systems의 ProJet MJP 5600 다중 재료 복합 3D 프린터를 만나보세요.

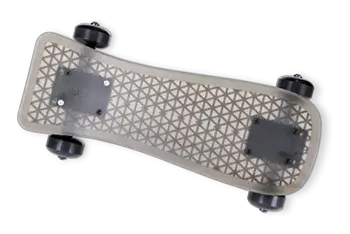

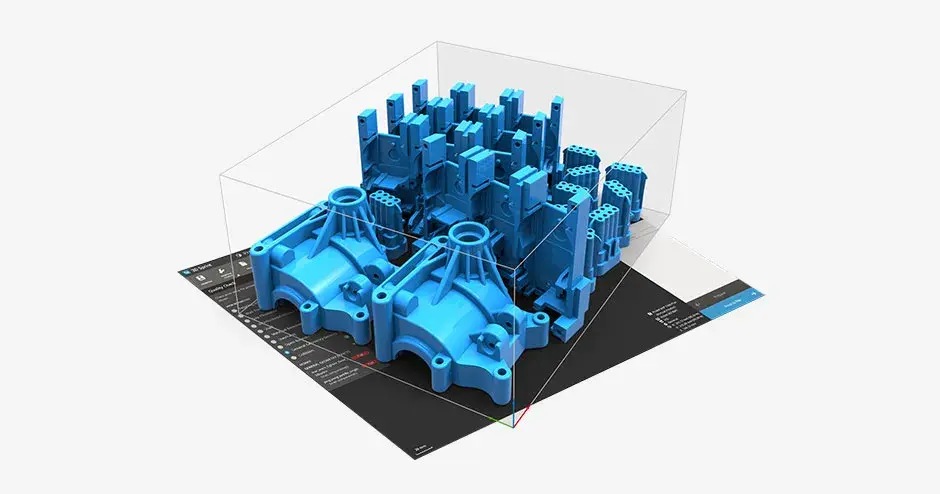

ProJet MJP 5600은 동종 등급의 타사 프린터 대비 2배 빠른 프린트 속도로 바로 사용 가능한 파트를 제공합니다. 이러한 MultiJet 3D 프린팅 솔루션은 전체 빌드를 신속하게 생산하고, 자동 후처리 덕분에 다른 공정 대비 최대 4배 빠른 청소 방법을 제공합니다. 다른 멀티젯 프린팅 장비보다 50% 큰 빌드 볼륨과 고성능을 통해 빌드당 최대 0.5미터 더 긴 파트 또는 여러 작은 파트를 프린트할 수 있습니다.

다양한 소재가 사용된 원형은 Clear, White 및 Black을 혼합하여 제품 구현 의도를 전달하고 마감 제품 시뮬레이션이 가능합니다.

ProJet MJP 5600은 우수한 형상 자유와 파트 기능을 다음과 함께 제공합니다.

경질 및 엘라스토머 재료로 사실적인 의료 모델 인쇄

폭넓은 기계적 성능 다양성을 제공하는 ProJet MJP 5600은 여러 응용 분야에 대해 놀랍도록 사실적이고 기능적인 원형 및 패턴을 제작하는 다중 재료 복합 프린터입니다. 이 멀티젯 프린팅 장비는 다양한 크기의 오버몰딩 부품, 다중 재료 어셈블리, 유사 고무 구성요소, 지그 및 고정 장치, 다이 등을 제작할 수 있습니다.

ProJet MJP 5600은 유사 PolyJet 장비보다 최대 두 배 빠른 프린트 속도를 제공합니다. 또한 대형 제작 용적으로 ProJet MJP 5600의 기능을 활용하여 경쟁사의 다중 재료 3D 프린터* 대비 부품 비용을 최대 40% 절감할 수 있습니다.

*Stratasys의 Objet350 Connex3™ 및 Objet500 Connex3™과 비교

멀티젯 프린팅 품질, 속도 및 사용 편의성 제공

SLA 품질 및 정확도를 위한 중간 범위 통합 솔루션