Figure 4 HI TEMP 300-AMB는 업계 최고의 고내열성 소재로서 HVAC, 소비자 가전 제품, 모터 인클로저, 고정자, 금형 등에 적합합니다.

초고내열성과 강성을 자랑하는 업계 최고의 플라스틱 소재로서 온열 조건이 열악한 환경에 적합합니다.

Figure 4 HI TEMP 300-AMB는 업계 최고의 고내열성 소재로서 HVAC, 소비자 가전 제품, 모터 인클로저, 고정자, 금형 등에 적합합니다.

Figure 4® HI TEMP 300-AMB는 높은 열 저항성을 필요로 하는 분야에 사용되는 초고온 플라스틱입니다. 응력이 낮거나 높은 상황 모두에서 300°C 이상의 열 변형 온도(0.455 및 1.82 MPa에서의 열 변형 온도)를 자랑하는 이 소재는 HVAC, 가전 제품, 모터 인클로저, 고정자, 금형 등을 포함한 분야에 사용하는 고온 부품의 테스트에 적합합니다. 2차 열경화 후처리가 필요하지 않습니다.

전체 기계적 특성은 해당되는 경우 ASTM 및 ISO 표준에 따라 제공됩니다. 모든 부품은 최소 40시간, 23°C, 50% RH에서의 ASTM 권장 표준에 따라 조건이 지정됩니다. 소재 특성에는 물리적 및 기계적 특성과 열, UL 가연성, 전기적 특성(유전 강도, 유전 상수, 손실 계수 및 체적 저항)이 포함됩니다.

Figure 4 기술은 기계적 특성이 등방성인 부품을 프린팅합니다. 따라서 XYZ축 중 하나를 따라 프린팅된 부품은 유사한 결과를 갖습니다. 가장 높은 기계적 특성을 갖도록 부품의 방향이 정해질 필요가 없어 기계적 특성에 대한 부품 방향의 자유도가 더욱 향상됩니다.

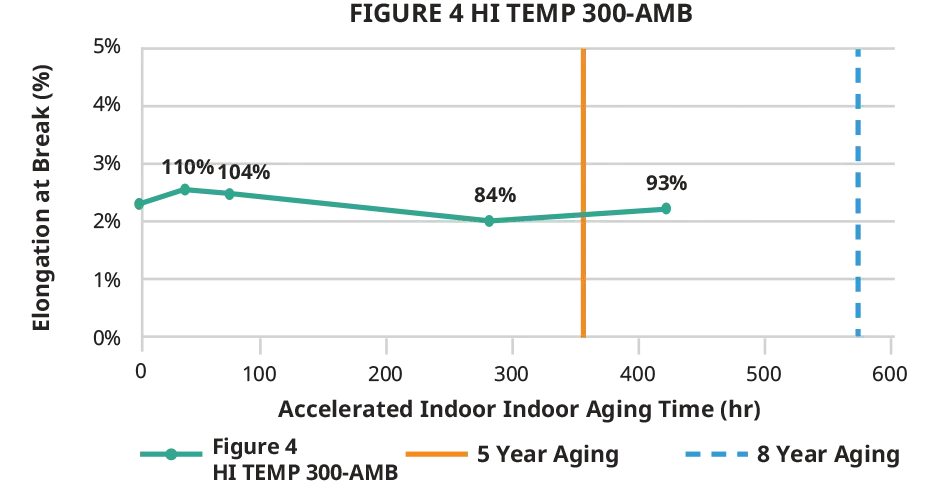

Figure 4 HI TEMP 300-AMB는 장기적인 환경 UV 및 습도 안정성을 제공하도록 엔지니어링되었습니다. 이 소재는 지정된 시간 동안 최초 기계적 속성을 높은 비율로 유지하는 테스트를 거쳤습니다. 작업 또는 부품에 대해 고려할 실제 설계 조건을 제공합니다.

이 차트는 데이터 세트의 샘플링을 보여줍니다. 전체 데이터 시트에는 인장 강도, 연신율, 인장 탄성률 및 충격 강도에 대한 실내 및 실외 안정성이 포함됩니다. 실제 데이터 값은 Y축에 있으며, 데이터 지점은 최초 값의 비율(%)입니다.

ASTM D4329 표준 방법에 따라 테스트됨.

ASTM G1554 표준 방법에 따라 테스트됨.

탄화수소 및 세척 화학물질과 소재의 호환성은 부품 응용 분야에 중요합니다. Figure 4 HI TEMP 300-AMB 부품은 ASTM D543 테스트 조건 및 USCAR2 테스트 조건에 따라 밀봉 및 표면 접촉 호환성 테스트를 거쳤습니다. 인장 강도(MPa)는 다음과 같습니다. 전체 데이터 시트에는 인장 탄성률, 연신율 및 노치 충격 강도에 대한 추가 데이터 표가 포함되어 있습니다.

* 참고: 일부 국가에는 일부 제품과 소재가 제공되지 않을 수 있습니다. 현지 영업 담당자에게 제공 여부를 문의하시기 바랍니다.

보증/면책 조항: 해당 제품들의 성능과 특징은 프린팅 변수 및 후처리 조건, 테스트 장비, 제품 응용 분야, 작동 조건, 최종 사용 목적에 따라 달라질 수 있습니다. 3D Systems는 특정 용도의 적합성이나 상품성 등을 명시적, 묵시적 또는 어떠한 방식으로도 보증하지 않습니다.

고온에서 살균 및 테스트가 가능한 강성의 반투명 소재

실리콘 및 다른 소재를 주조하기 위한 툴링의 제조에 사용되는 공정 최적화된 소재.

생산 부품에 대한 생산 등급, 강성 소재

Figure 4 HI 300TEMP 300-AMB 플라스틱 소재의 고내열성 고정자는 고온 환경에서 테스트하거나 사용하는 데 적합합니다.

최고의 SLA와 광 투사 기술을 결합하여 탁월한 성능과 생산성을 제공합니다.

사용자 정의가 가능한 업계 최초의 직접 디지털 생산용 완전 통합형 공장 솔루션

비즈니스 성장에 따라 확장 가능하도록 설계된 반자동 3D 제조 솔루션

매우 신속하게 저렴한 비용으로 당일 원형 제작 및 소량 생산

도구가 필요없는 제조를 위한 반복 가능한 정확도로 고속, 고정밀 구현